Modular Construction

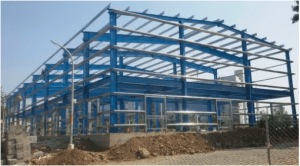

Modular building, or just prefabrication, is focused on the building use of repetitive units, modes, machinery, and so onwards, shaped off-site in a factory setting. That’s why, as Jeffrey Molavi and Drew L. Barral conversed, its proper application would need many contemplations to design, management, and direction.

Costs vary between projects for numerous explanations. Seeing labor, an individual needs to think about barriers to mission conclusion, productivity ranges, and also exposure on uncontrollable factors (i.e. weather consequences). However, with a modular structure, these essential factors are essentially paid down. On the flip side, when seeing the extensive preparation necessary for job’s delivery of pre-fabricated components, there’s a lot of room for mistake, like the incompetence of these pre-fabrication providers to give quality, flawless elements. In the same way, there’s an inverse relationship between externally, the fiscal responsibility of restarting the construction approach, and the administrative direction of stakeholders with varying histories and intentions, for example, Profit maximization of their role.

To notice, you can find significant prospective advantages of modular structure, such as its capacity to directly participate and coordinate one of the various industrial transactions (i.e., electric, mechanical, plumbing). As an instance, it is not as obstructive to put in piping and ductwork after completing its inner function, than previously or during this procedure. Thus, sub-contractors are somewhat more embracing to the after effects of this pre-fabrication preparation sector of the job’s structure. Pros arise in the accession of pre-fabrication procurement pursuits, which range from additional expenses of material, transport, and setup, to alterations in structure management responsibilities and superior review difficulties. That’s the reason why it’s more challenging to make sure reliability from most of the subroutines of this job’s structure. To offset these effects, Molavi and Barral planned to invent a secure way of using pre-fabrication economically, concerning cost and constructability, dependent on real-world building endeavors.

They picked an overall urban perpendicular building (i.e., office building) because their subject of analysis, to utilize its structure process’ insistent nature to learn more about the capacity for pre-fabrication for various construction transactions. As an example, the staircases, room inside, walls outside, window positioning, floor design, etc., are alike enough to draw on connection and/or employ comparatively simple alterations in their components, hence permitting a big selection of pre-fabrication usage. Afterward, to optimize the benefits of prefabrication, if enabled, contractors may utilize reliable, multi-performance (regarding transactions) providers and sub-contractors to reevaluate divisional management. Similarly, they can use a small number of stakeholders associated with devoting coordination to lessen risks of collapse in procurement and administration. Afterward, overall vulnerability will be focused on punctually efficacy, communicating, and pre-fabrication quality, thereby diluting its original extent in the conventional structure. Because of this, sustainability could be accomplished during its highest potential, though determined upon its corresponding production speed and gratification.

This newspaper is of use just as a benchmark origin from later-released, empirical research newspapers about pre-fabrication, thus its flaws: a lack of information and utilization of underlying assumptions. But if attention is its own standing to the starting phases of development and understanding of their prefabrication technology and application, notably involving sustainability. As a result of the implied implications of this reverse relationship between sustainability and constructability, it will become apparent an investigation to your present situation is essential to some much greater understanding.

Cost-benefit analysis

Even though pre-fabrication to understood to provide substantial benefits to ecological sustainability and constructability, employing it onto an extensive selection of infrastructural projects is most improbable for developed countries due for their urbanization consequences. Regarding China, since Jingke Hong,” Geoffrey Qiping Shen, Zhengdao Li, Boyu Zhang, along with Wangqiu Zhang are finding, structure stakeholders regularly credited this on the current absence of transparency in violating feasibility and appraisal. Since there is little data out there to reference these hurdles to economic reduction before the analysis entirely, the team researched to create a robust cost-benefit investigation for its utilization of pre-fabrication for construction in China.

Determined by the residential building structure, costs related to pre-fabrication are displayed in the chart below. Especially, substances (concrete and steel) cost probably the absolute most, because of their enormous amounts and higher market price, followed closely by labor input. In comparison to classic structure, prefabrication used more complex transport logistics to stop damaged components, which also led to the fee difference. In general, to know pre-fabrication costs in detail, an individual might examine the material durability of these pre-fabricated components, dependent on contract specifications and basic goals, in addition to their participation in the building procedure.

The team found, a regression analysis, which the price intensity was positively related to the pre-cast rate (the proportion of pre-fabrication employed as a whole cement section of the building arrangement). This will signify that the financial expenses of embracing pre-fabrication surpassed the advantages of their developments on constructability, hence causing your discouragement in using pre-fabrication. By a further breakdown on cost incrimination of pre-fabricated components, the cost rose dependent on the area of related aspects like fabricating, mixed job, and logistics sophistication. The latter may be broken up to labor expenses, consultant companies, and also drawing/architectural work. To notice these sub-factors are primarily determined by geographical dynamics, like the industry’s adulthood and local access to pre-fabrication providers and resources.

As a result of the robust relationship between price payable and pre-cast pace, the research demonstrated a fantastic requirement of cost-saving plans. Proposals comprised maximizing pre-fabrication (through mass manufacturing (constant mass orders) to enhance constructability efficacy while using this cost advantage of this economics of scale. Since now the industrialization lack is employed to just a small part of the building, perhaps maybe not all of the structural and financial benefits are recorded. Afterward, it would be vital that you unite an environment friendly, multi-performance materials way of cost-effectiveness in the administration of components that are personalized. Additionally, the immaturity of this prefabrication market reflected at the fee incurred throughout on-site setup of prefabricated components needs to be addressed to minimize future battles. Externally, it’d be good for improving political participation on the market to promote pre-fabrication technology through financial incentives and support to stakeholders and providers.

The research design of the paper has been very well-developed, together with appropriate attention given to multiple facets of interests, for example, regional significances, specialty, industrialization and urbanization gap, etc. In spite of the range of assumptions used to produce and execute the research practice, these were accounted for in the plausible rationale and data analysis, in addition to further afield from the conversation section assimilated to my critique. At precisely the same period they used various techniques in merging the data, for example, construction and economics logistics. That’s the reason why, it seems that the sole weakness that this newspaper included has been that the real-world restraints and consequences in the research, on account of this prematurity though applicable circumstance of urbanization in China.

Conclusion

Up to now, environmental and economic sustainability was accounted for and when compared with constructability, to get an unbiased appraisal of the significance of the building procedure. Viability was reviewed per the lens energy consumption, in a bid to maximize a concrete arrangement’s embodied energy. Afterward, barriers and approaches to achieving were believed simultaneously to ascertain prospective alternatives. Next, modular structure, also termed pre-fabrication, had been first discussed and viewed in its own sustainability prospect of its construction procedure. In a recent circumstance, a cost-benefit investigation has been examined, with regard to China’s urbanization, to detail the consequences of pre-fabrication, for both management and technology, at the construction market.

Across areas, such as sustainability, there is much consideration to definite life cycle, even in its own economical breaking and service duration, to get a building’s job deadline. Embodied energy has been likewise an integral variable of sustainability, which is why careful manipulation and supply of non-energy-intensive substances through reinforcement held the prospect of greater efficacy. Seeing pre-fabrication, after closing study of adulthood and constructability, their reverse relationship left room for the outside promotion of usage. From the different circumstance of urbanization, much space has been made for cost efficacy and material efficacy, in spite of the observed advantages of prefabricated metal buildings. Last but not least, most newspapers indicated potential political participation, mostly financially, in overcoming the economic struggles of their markets to the business. If that’s the circumstance, it’s more imperative to validate that the cost worth and produce a multi-performance process of ensuring consistency and accuracy before policy execution.

In reaction to “what exactly may be the tradeoff between optimization and sustainability of tangible use within a structure circumstance?” , finishing the literature inspection there isn’t any acceptable answer. Per day a structure perspective, assuming that constructability suggests optimization, the detected, real-world connections hold inconsistencies among endeavors about concrete usage’s optimization. That is mainly related to pre-fabrication application, even more, commonplace in developing countries. If that’s the scenario, it will be more accurate to think about the interrelations of these above aspects to understand and signify their comparative relevance or impact of the construction market. To notice it will become sensible due to research limitations, this procedure could be ineffective for cost and time. Afterward, the pace of this market which functions the could be viewed relatively stagnant, and that introduces an issue for notably urbanization.

Authors Note:

Coast to Coast Carports is one of the best providers of custom metal buildings and steel constructions such as barns, metal carports, steel garages, RV covers and workshops for all your requirements. You can personalize any structure and fix it at any level surface close to your house, factory, or site.