Nowadays, it is pretty easy to think that air compressors are prevalent things in every workshop. But only a decade or two back, you would hardly find a test compressor in a workshop or a factory. An air compressor is a machine that takes air at the atmospheric pressure as its input and delivers high-pressure air. With this technology, the engines transform power into potential energy. Inside the compressor, the air becomes compressed into a vessel or the holding chamber. Therefore, the energy is being stored within that vessel until it is not released. The pressure inside the holding chamber keeps moving until it reaches the secret level.

Based on types, sizes, and pressure, limited you can categorize air compressors into different parts. But if you simplify things, you will find two models of air compressors – single-stage air compressors and 2 stage air compressors. So here are the details of a test compressor.

You can divide the supply facility into two forms of air compressors, such as electrical and gas. Either the mechanical device of the test compressor is highly powered by electricity or by gas. Although, each of them has two variants, incredibly portable and stationary compressors.

Table of Contents

Stationary Compressor

Air compressors of these different square measure based on the size. These square measures are closely-held by the outlets and home-owners. The square measure for such compressors is placed in a closed and challenging position and stays stationary. Moving and shifting of such significant and massive instrumentality isn’t convenient and straightforward. Amid massive storage chambers, these compressors sometimes have attitude power and serve their offer for an extended length.

Movable test compressor

On the other hand, these squares measures are smaller in size. The vessel is additionally smaller than the stationary ones in terms of size. Unlike the previous variant, these compressors have handles and wheels that allow you to shift the instrumentality from one place to another. These square measures are appropriate for swift jobs.

Features of test compressor:

- Here are the most common features of air compressors that will help you understand how it works.

- The exhaust system of the test compressor is entirely adjustable according to the needs.

It has a thermal protection feature. - There is also a wetness unharness valve available in the compressor.

- There is an output clock on the front side that shows the pressure of the airflow.

- Compressors can store air in compressed conditions.

- It also has an Oil-free pump.

- There are multiple couplers present in the compressor.

- Accessories and Tools are also present.

The Basic Piston Functionality

The functions of air compressors are based on a simple principle. The volume of the air decreases when the air is compressed, and the pressure increases accordingly.

The initial part is a reciprocating piston. Some compressors employ rotating impellers to create air pressure. Those compressors that are built with a reciprocating piston are more common. So, if you’re familiar with how internal combustions work, the piston compressors work similarly.

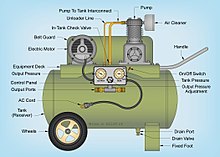

Every reciprocating piston compressor has a connecting rod, crankshaft, valve head, and piston. It would help if you had power for the entire mechanism to work. Air compressors are generally powered by gas or electricity, depending on the model. Most test compressors also have a tank that is there to store the compressed air to keep the air pressure within an acceptable range during powering various air tools.

Dual Piston Function

There are different ways to this approach, but the main principle is always the same. Dual-piston compressors are also pretty standard, and they work in the same process just like the single-piston counterparts do. The only difference is there are two strokes per revolution and not one. The most common difference of a dual-piston compressor is the two-stage compressor, which uses one piston to pump air into a second cylinder, creating more significant pressure.

To keep the pressure within the proper limit, you need to prevent the tank from exploding, and the air compressor has a switch that cuts the motor’s power when the pressure inside the tank has reached the limit.

This measurement of the pressure stays inside the tank and air-line, respectively. In case the pressure switch doesn’t work, there is also a safety valve and an unloader valve. This valve is there to reduce pressure inside the tank when the compressor is in use.

These all are the functions of a good air compressor. It will be very effective on different types of work. If you would like to buy a test compressor for your work, you can easily buy them online. You can also buy them from the outlets, which will help you know the features properly from the company executives.

Maintenance of air compressor

It is always essential to maintain any electronics product. And when it comes to the air compressors, maintenance at a regular interval is very important for safety. So here are some maintenance measurements of suitable test compressors.

- The unharness the wetness unharness valve once each use so to produce the equipment from oxidation.

- You need to check all the parts and valves regularly.

- It would be best if you also kept in mind that the air fillers square measure should be in correct condition and square measure operating are adequate.

- If you find the hose broken, then you must replace that with a new one. Hence, checking the hoses is very important.

- Also, make sure that the security valve of the air compressor is working well.

- Never miss lubricating the mechanical device on time.

- The timely improvement of the fuel tank is also a significant part of maintenance.

So this is all about a brief description of an air compressor, the types, and how it works. For any compressor, regular maintenance is essential. Otherwise, it could be a big problem for everyone. Also, lubricating the devices regularly is very important to keep the compressor up and running for a long time.